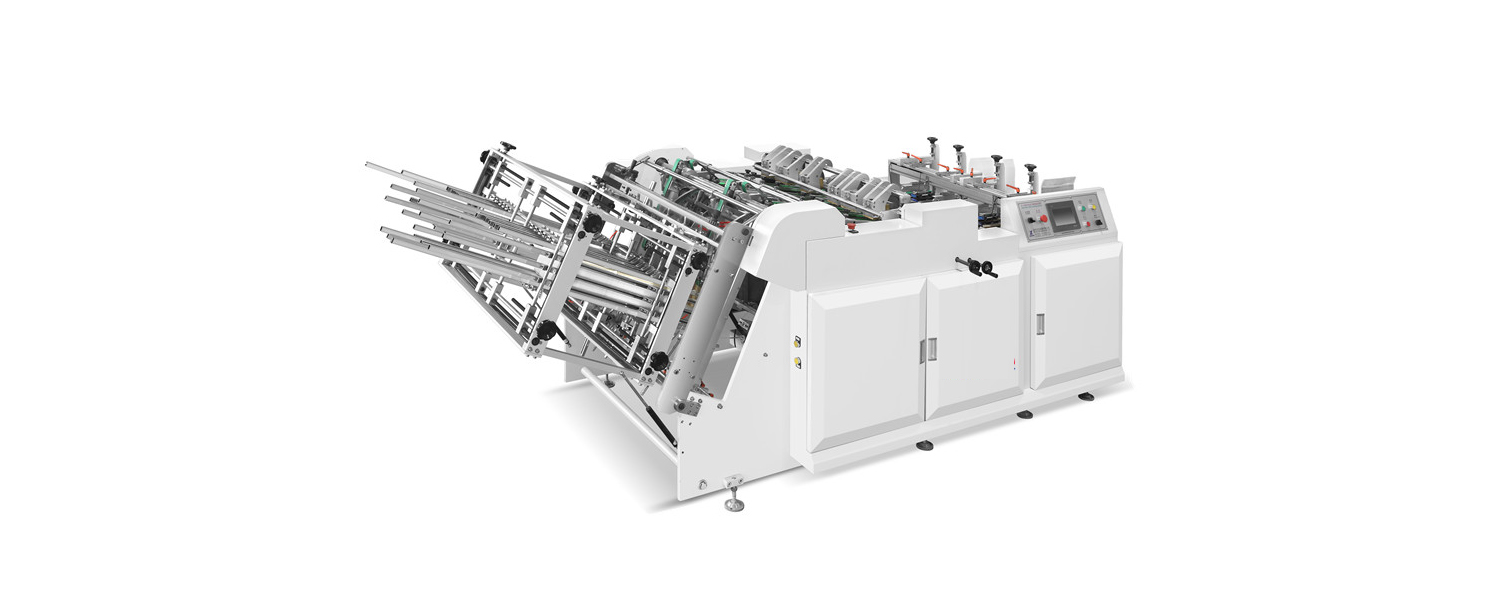

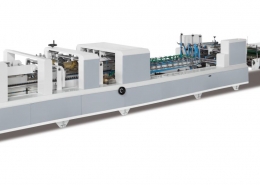

Technical specifications ZX-1600 Double Workshop Carton Erecting Machine

Double workshop 3D carton machine by pressing the paper directly, not only can be dressed up solid or liquid food, but also reduced the traditional paste box machine boxes should be its open action, greatly shorten the time of boxes of food, meet the environmental protection, health, sealing and rapid flow of fast food to the requirement of packaging. The whole machine conforms to “CE” certification, it also has the characteristics of accurate and stable transmission, high production efficiency and small floor area.

On the same machine, only need to change the mold to be able to manufacture the different specification meal box, the chip box, the stereo box, the hamburger box and so on the product.

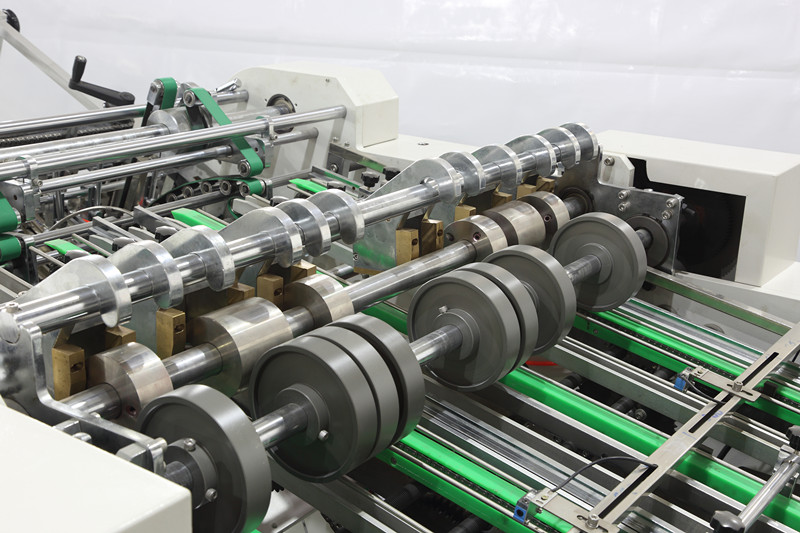

This machine adopts water-based adhesive gluing device, which can achieve high efficiency and high accuracy. Water-based adhesive is a water-soluble adhesive used for food grade glue. Most of the high quality sealed bearings, (to prevent dust, liquid into the bearing life) long life, good stability. All adopt high quality synchronous belt to drive, make the machine running process almost no error. The main mold is made of pine wood, and the mold replacement has high efficiency. Can automatically collect accumulation inventory finished products. Add counting calculator according to customer requirement. The machine adopts PLC intelligent control system, which automatically stops when there is no paper stuck.

| model : | ZX-1600 | |

| 生产速度 speed: | 100-320pcs/min | |

| 原材料 Material: | 200-620gsm

Corrugating paper thick:1.6mm |

|

| 纸盒规格 box size: | Length: | L100-450mm |

| Degree:5°-45° | ||

| Width: | B100-600mm | |

| Height: | H 15-200mm | |

| 功率Power : | 6kw | |

| 用气量Air requirement: | 0.5Mpa, 0.4cube/min | |

| 电压Voltage: | 380V 50Hz | |

| 尺寸size: | 3600*1850*1700mm | |

| 重量weight: | 2800kgs | |