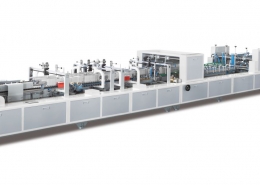

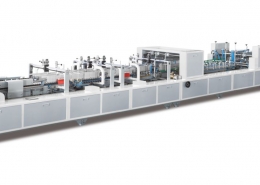

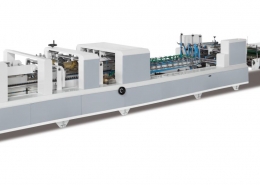

BMW SERIES 750/920L-automatic corner cutting and wire pressing window patching machine has been the latest model pushed to maket. with the functions of both simple patching and film patching with creasing, this machine can realize the double creasing – double cutting- circular angle- Round hole- Environmental protection loop mark on PVC. PET. PP. OPP film with the thickness of 0.08- 0.3mm. original creation transverse cutting film high speed and quiet, peculiar gluing assembly can be disengaged to avoid glue on belt in case of no paper. full-digital control function all parameters can be fine-tuned during operation. It is also euipped with multi-sensor detection of each station, real-time monitoring of running state and abnormal speed rduction alarm functions. from our continual improvement and philopophy of humanized design, so that it is easy to operate and excellent in efficiency, accuracy and stability.

Technical parameters

| Model | BMW-750L | BMW-920L |

| Papersize | W730*L650mm-100*150mm | W900*L680mm-150*150mm |

| Windowdimension | W350*L300mm-50*50mm | W380*L300mm-50*50mm |

| Paperweight | Cardboard:200~2000g/m2 Corrugated board:1-6mm | Cardboard:200~2000g/m2 Corrugated board:1-6mm |

| Filmthicknes | 0.1~0.3mm | 0.1~0.3mm |

| Positioningaccuracy | Top/bottom±0.5mm left/right±0.1mm | Top/bottom±0.5mm left/right±0.1mm |

| Mechanicalspeed | Up to 8000 sheet/hour | Up to 8000 sheet/hour |

| Powervoltage | 380V/50HZ(Three phase) | 380V/50HZ(Three phase) |

| Machinepower | 8.5KW | 10.5KW |

| Machineweight | 3000KG | 3200KG |

| Overalldimension | L6800*W1400*H1700mm | L7000*W1570*H1700mm |

Specificationsorsizesmaybechangedwithoutnoticeduetomechanicalequipmentupgrades!

EQUIPMENT CHARACTERISTICS

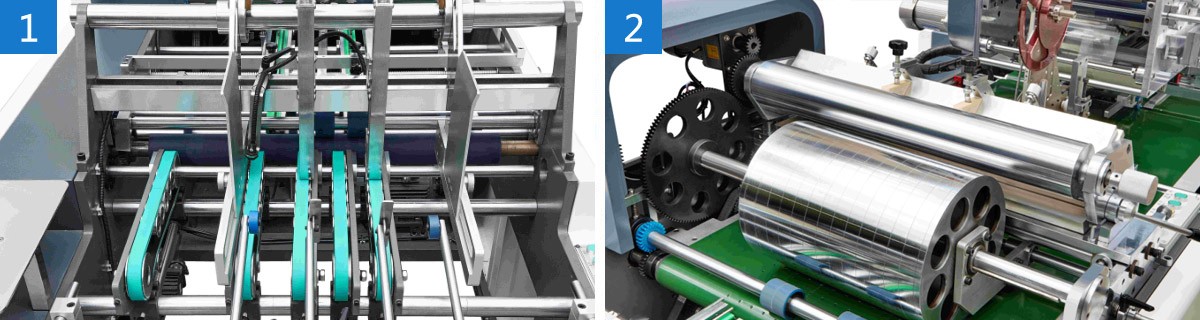

1,Paper Feeding Assembly

This machine used the Japan imported belt to draw out the paper from the bottom and non stop machine used to continuously add and feed the paper;intermittent belt for paper carrying and feeding has used the servo control, the intermittent paper carrying length can be adjusted on the human machine operation interface according to the length of paper; multiple carring belts have been equipped with gear and gear rack device which can adjust the position of belt, be more left or more right.

2,Gluing Assembly

One high-hardness roller circulating glue used, the roller besement adopts center- oriented device to adjust the thickness of glue; with flexo template gluing, the shape can be carved according to the product need. The roller to install the template has a reference line making the template exact, convenient and fast to install. Gluing position can be adjusted more left or more right, the position regulator can adjust it to more front or more behind, the non- stop machine adjusted the position to all directions needed, The rollers can be disengaged to avoid glue on belt in case of on paper, Rubber roller can be towed out, cleaning and maintenance is more convenient.

3,Filming Assembly

Independent servo control system is adopted Users can adjust the film length as per product size without shutdown. The baxe material can be adjusted horizontally; Meanwhile, chamfer lines are cut automatically ater the paper is posisioned accurately according to the above regulations attach the films to paper box and cut the film via automatically transverse cutter The precision of film attachment is up to ±0.5mm.

4,Paper Collecting Assembly

Imported soft belt conveying can prevent product crushing, Paper is collected tidily in a sandwiching structure, Independently adjustable speed, selective use according to product, which ensures perfect quality.

5,Appliance parts

The whole machine adopts PLC program control. All kinds of electronic components and detector switches are made in Germany, Taiwan and Japan etc.

6,Film Heating System

Employ electromagnetic heating system. The heating roller is made of high hardness steel, Mirror chrome plating, At the same time equipped with two sets of film pulling device; Guarantee drawing film speed synchronization, So as to ensure that the film does not wipe flowers. Reslize the function of auxiliary flat film.

7,Double faced adhesive tape System

Innovative double- sided adhesive technology, can adopts to most types of double- sided adhesive. Double-sided adhesive incision for the tooth mouth, will not cause the damage to the product itself. According to the actual situation, select double- sided adhesive device.