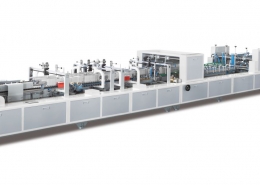

High Quality Automatic Thermal Laminating Machine Price

Parameter:

| Model | ZWFM-1100 |

| Max.Paper Size | 1000X1050mm |

| Min.Paper Size | 285X350mm |

| Paper Thickness | 100-500gsm |

| Film Thickness | 8~25 micron |

| Max. Speed | 80m/min |

| Voltge | 380V 50Hz |

| Total Power | 36KW |

| Working Power | 20~30KW |

| Lap Accuracy | ±2mm |

| Lamination Pressure | 5~15Mpa |

| Hight of Feeder Pile | 1000mm |

| Hight of Stacker Pile | 1000mm |

| Dimension (L*W*H) | 8600×2100×2100mm |

| Packaging Size(Wooden Pallet)

(L*W*H) (40GP) |

2200x2100x2200mm(Feeder part)

1600x2100x1900mm(Lamination Part) 1200x2100x1800mm(Slitting Part) 2200x2100x2100mm(Stacking Part) |

| Total Weight | 6000 kg |

Introduction

ZWFM-1100 fully automatic thermal lamination machine is designed for thermal (pre-coated) lamination, easy to use without glue coating unit. Features high automation, high laminating speed, high accuracy, electrical appliance is centralized by programmable system, touch screen easy to operate, with high cost-performance.

A heated roll laminator uses heated rollers to melt glue extruded onto lamination film. The film is applied to the substrate such as paper or card by pressing roller in turn. The main purpose of laminating with this machine is to decorate or protect printed documents or images. The high quality automatic thermal laminating machine we produced, have met high standard as Europe and exported to worldwide with competitive price. At the same time our company already gain good comments and fame around oversea market. Meanwhile we own advanced production technology and senior designers for OEM and ODM. Please contact with us and inquiry for low price in bulk.

Configuration & Functions

1. Automatic High Speed Feeder: Adopt high speed pneumatic offset feeder, speed up to 100m/min. Pre-stacking system can realize non-stop feeding, obviously improving work efficiency.

2. High Accuracy Lap Control: Servo-controlled lap within ±2mm, synchronizes with feeder, high accuracy front lay and pnuematic side lay regulator ensure accurate and stable position.

3. Automatic Shutdown Protection System: Equipped with photoelectrically controlled automatic shutdown protection devices, in case of paper shortage, paper broken and paper overlap.

4. Thermal film laminating machine System:The 360mm diameter mirror laminating roller is equipped with Electromagnetic Heating Device, can realize high speed booting and heating, 2 times heating performance than traditional oil heating device meanwhile save much power consumption.

5. Automatic Hydraulic System: The hydraulic system automatically provides stable and large pressure to ensure high quality of lamination.

6. Man-machine Interface System:Equipped with color touch screen, easy and convenient to operate. The operator can view the machine’s working status at any time from the touch screen.

7. Air Shaft and Tension Control System:Adopt air shaft, easy to load film, accurate film position by the graduation of the air shaft. At the same time the intelligent tention system easy to control the tention of film, increase laminating performance.

8. Slitting System:Adopt disc knife, coordinated with pneumatic pull and separating device, can slit BOPP and OPP film perfectly.(If you use PET or thin foil, we have Chain knife slitting machine optional.)

9. Anti-Curvature System: Adopt corrugrated delivery and anti-curvature system, especially designed for thin paper, avoid paper curvature.

10. Automatic Stacker: Equipped with IR sensor, automatically count the sheets. Three-direction high speed pneumatic stacker can collect the sheets automatically and flat without stopping.

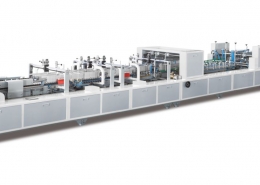

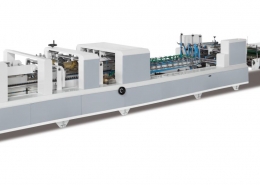

Actual Photo

1. Feeder Part

Adopt high speed offset feeder and chain drive non-stop pre-stacking system, can feed sheets up to 100 m/min, smoothly without stop, obviously increase the efficience. 2. Delivery Platform

2. Delivery Platform

Equipped with high accuracy front lay and pneumatic side lay regulator, accurate position, can deliver sheets in high speed without curvature.

3. Hot Powder Cleaning(Optional)

Hot powder cleaning machine, especially for dark paper, improve the laminating performance.

4. Lamination Main Part

Adopt 360mm diameter mirror laminating roller, equipped with electromagnetic heating system, high heating speed and performance, 2 times heating performance than traditional oil heating device meanwhile save much power consumption.

The hydraulic system automatically provides stable and large pressure to ensure high laminating quality.

Air shaft with dividing ruler, can adjust the position of film roll accurately, easy to load film. The tension of film is adjusted accurately by the tension controller.

Equipped with color touch screen and man-machine control panel, easy and convenient to operate. The operator can view the machine’s working status at any time from the touch screen.

5. Slitting Part

Adopt disc knife, coordinate with pneumatic pull and separating system, can slit BOPP and OPP film perfectly.(If you use PET or thin foil, we have chain knife slitting machine optional)

6. Stacking Part

Automatic stacker, stack sheets in 3 directions fast, makes sheets pile aligned, convenient to transport and ready for next process. 7. Stacking Part

7. Stacking Part

Automatic stacker, stack sheets in 3 directions fast, makes sheets pile aligned, convenient to transport and ready for next process.

Main Parts

|

Touch Screen |

Chinese Taiwan Weinview |

|

Encoder |

Japan Omron |

|

Inverter |

China Kewo |

|

AC Contactor |

France Schneider |

|

Intermediate Relay |

France Schneider |

|

Push Button Switch |

China Yijia |

|

Small broken Fuser |

China Chint |

|

Programming Controller |

Chinese Taiwan Delta |

|

Servo Drive |

Chinese Taiwan Delta |

|

Motor 5.5KW |

China Dongfang |

|

Electromagnetic Auxiliary Heating System |

China Shenzhen |

|

Converters |

France Schneider |

|

Digital Control Devices |

Chinese Taiwan Delta |