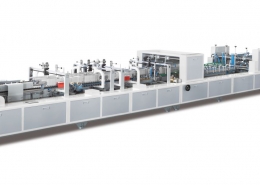

QLFM-1100B Industrial Automatic Paper-Plastic Laminating Machine

Product Description

QLFM-1100B industrial automatic paper-plastic laminating machine is a high-quality, easy-to-operate, energy-saving and environmentally-friendly laminating machine. The laminating machine industry will provide the industry with a way to improve the quality of printing materials, reduce costs, and create high profits. Industrial paper laminating machine is an ideal model for printing plants to eliminate the traditional high energy consumption and serious pollution of paper-plastic composite equipment after printing. In order to meet the requirements of customers for the laminating process, we combine the latest laminating technology with the automatic laminating equipment introduced by the team after years of research and development and experiments. QLFM-1100B automatic paper laminating machine industrial can be widely used for packaging teaching materials, books, periodicals, picture albums, manuals, wall charts, maps and audio-visual products, handbags and boutique boxes.

| Property | Data |

|---|---|

| Model | QLFM-1100B |

| Max.Paper Size | 1000X1050mm |

| Min.Paper Size | 285X350mm |

| Paper Thickness | 100-500gsm |

| Film Thickness | 8~25 micron |

| Max. Speed | 80m/min |

| Voltge | 380V 50Hz |

| Total Power | 65KW |

| Working Power | 25~45KW |

| Lap Accuracy | ±2mm |

| Lamination Pressure | 5~15Mpa |

| Coating Glue Amount | 3~8g/m^2 |

| Hight of Feeder Pile | 1000mm |

| Hight of Stacker Pile | 1000mm |

| Dimension (L*W*H) | 9600×2600×2700mm |

| Packaging Size(Wooden Pallet) (L*W*H) (40HQ) |

1850x2100x2200mm(Feeder part) 2360x2200x2550mm(Lamination Part) 2200x2100x1850mm(Slitting Part) 2200x2040x2200mm(Stacking Part) 1900x1500x1600mm(Powder Removing Part) (Optional) |

| Total Weight | 9500 kg |

Automatic Paper-Plastic Laminating Machine Details:

1. The paper feeder part of the automatic paper industrial laminating machine

The high-speed offset feeder and chain uninterrupted pre-stacking system can feed paper at speeds of up to 100 m/min, smoothly without stopping, and significantly improve efficiency.

2. Industrial laminating machine delivery platform

Equipped with high-precision front paper discharge and pneumatic side discharge regulator, the position is accurate, and the paper can be conveyed at high speed without bending.

3. Hot powder cleaning of industrial laminating machine (optional)

Thermal powder cleaners (especially cleaners for dark paper) can improve film performance.

4. Lamination main unit

Using a large mirror heating roller with a diameter of 800mm, equipped with an electromagnetic heating system, the heating speed is fast, and the performance is high. At the same time, the thermal circulation system and the hot air circulation system can save a lot of energy.

The big mirror laminating roller is also equipped with an electromagnetic heating system, which is used in conjunction with a big rubber roller to ensure the laminating performance.

The electrical appliances are centralized by a programmable system and driven by a dual electromagnetic heating system.

5. Glue coating part

The use of high-precision glue regulator can control the knife to easily and accurately adjust the thickness of the coating film, saving a lot of glue consumption. The mirror coating roller ensures uniform glue.

The air shaft is equipped with a partition regulator, which can accurately adjust the position of the plastic film roll, and it is easy to load and unload the film. The tension of the film is precisely adjusted by the tension controller.

Equipped with a 10-inch color touch screen, easy to operate. The operator can check the working status of the machine at any time through the touch screen.

6. Slitting Unit

The high-speed chain knife slitting machine specially designed for PET and thin foil can cut most film materials perfectly. It is easy to adjust by entering data into the setting panel.

The disc knife assists the slitting, and the pneumatic drawing and separation system is used to slit BOPP and OPP films without a chain knife.

| Part | Origin |

|---|---|

| Servo System | Special servo for chain knife |

| Ultrasonic Double Detector | Original German import |

| Touch Screen | Chinese Taiwan Weinview |

| Encoder | Japan Omron |

| Inverter | China Kewo |

| Chain | Germany Renod |

| AC Contactor | France Schneider |

| Intermediate Relay | France Schneider |

| Push Button Switch | China Yijia |

| Small Broken Fuser | China Chint |

| Programming Controller | Chinese Taiwan Delta |

| Servo Drive | Chinese Taiwan Delta |

| Servo Motor 1.1KW | Chinese Taiwan Delta |

| Motor 5.5KW | China Dongfang |

| High Speed Feeder | China Ruida |

| Push Button | France Schneider |

Specification mentioned here is subject to change without notice.

Highlights

1. Programmed paper feeder: The exact plan of the paper feeder head makes it conceivable to easily pass on good and bad paper. It embraces a consistently factor speed gadget and is outfitted with programmed edge control to adjust to various paper taking care of. For muddled spotlight, it is helpful to modify the overall situation of the spotlight and the paper stack during activity. A unique continuous paper taking care of gadget, outfitted with an assistant worktable, can renew paper during paper taking care of to guarantee persistent creation. The most extreme paper yield speed can arrive at 100m/min.

2. The programmed paper take-up machine can take paper in three ways at fast, and can understand the take-up of single or different papers simultaneously. The paper heaps are flawless and helpful for transportation and resulting handling; the got paper can be consequently tallied by the infrared sensor.

3. The drying part embraces a huge mirror surface drying roller with a measurement of 800mm, and is furnished with an electromagnetic warming gadget, enhanced by a drying channel warm flow framework, which significantly lessens the warming time, improves the warming impact, and guarantees the nature of the item. covering. Simultaneously, the warm cycle framework can spare a ton of vitality. Utilization, along these lines controlling creation costs, while improving creation proficiency.