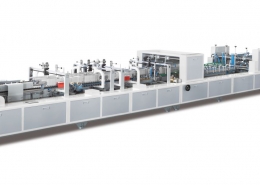

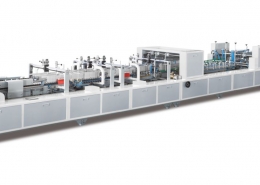

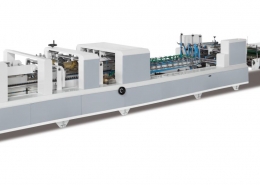

ZH-BH 4/6 Corner Automatic Folder Gluer

ZH-B 4/6 Corner Automatic Folder Gluer 1. INTRODUCTION: ZH-BH 4/6 Corner Automatic Folder Gluer is a multi function model, suitable for card board, EB flute corrugated board. This model has corectiondevice.Can select bottom lock device..Can make electrical adjusting. Has UV destroying device and…

1. INTRODUCTION:

ZH-BH 4/6 Corner Automatic Folder Gluer is a multi function model, suitable for card board, EB flute corrugated board. This model has corectiondevice.Can select bottom lock device..Can make electrical adjusting. Has UV destroying device and dust removing device for better gluing effect.

Functions: auto feeding, auto correction, creasing, auto alignment, pneumatic box pressing.

2.CHARACTERS:

1.Driving by synchronous belt,ensure smooth and accurate running.

2.Inverter driving,stable and power saving.

3.Use electric adjust,easy operate.

4.Automatic continuous feeding,use multiple belt with vibrating motor,(for higher configuration use drilled suction belt),to keep the feeding stable.

5.Automatic counting and kicking,quantity can preset.

6.Conveyer pressure adjustable according to the box to ensure best quality.

7.The machine is configured with remote control,Remote troubleshooting, update the program.

| Straight line box | |||

| ZH-B850-4/6 | ZH-B1100-4/6 | ||

| A | MAX | 850 | 1100 |

| MIN | 80 | 100 | |

| B | MAX | 1000 | 1200 |

| MIN | 60 | 60 | |

| C | MAX | 200 | 300 |

| MIN | 8 | 8 | |

| double sides box | |||

| ZH-B850-4/6 | ZH-B1100-4/6 | ||

| A | MAX | 850 | 1100 |

| MIN | 100 | 100 | |

| B | MAX | 800 | 800 |

| MIN | 70 | 70 | |

| C | MAX | 200 | 300 |

| MIN | 10 | 10 | |

| crash-lock bottom box | |||

| ZH-B850-4/6 | ZH-B1100-4/6 | ||

| A | MAX | 800 | 1100 |

| MIN | 180 | 150 | |

| B | MAX | 800 | 1000 |

| MIN | 40 | 60 | |

| C | MAX | 200 | 300 |

| MIN | 25 | 30 | |

| 4-corner box | |||

| ZH-B850-4/6 | ZH-B1100-4/6 | ||

| A | MAX | 770 | 950 |

| MIN | 140 | 180 | |

| B | MAX | 550 | 800 |

| MIN | 60 | 80 | |

| C | MAX | 120 | 150 |

| MIN | 20 | 25 | |

| 6-corner box | |||

| ZH-B850-4/6 | ZH-B1100-4/6 | ||

| A | MAX | 770 | 950 |

| MIN | 200 | 300 | |

| B | MAX | 500 | 800 |

| MIN | 80 | 80 | |

| C | MAX | 120 | 150 |

| MIN | 20 | 25 | |

3.Features:

4.Gluing system

| Input voltage | AC220V (±20%) 50-60HZ |

|

| Power | 480W | |

| Glue-like precision | ±1mm | |

| Gel-point | 4 types | |

| Model | HBS | |

| Guns | 3 | |

| To adhesives max viscosity | 3000mPas | |

| Each two-way transport efficiency | 6:1 | |

| Gas source input requirements | 2-8bar | |

| Weight | 25kg | |

| SIZE | 1280*480*600mm |

5.Plasma Surface Treatment

| Model | CLEAN-PL-5020 |  |

| Input voltage | AC220V | |

| Nominal power | 1500AV | |

| Plasma power supply frequency | 20-30khz | |

| Air supply pressure | 60L/m³ | |

| Dimension | 720*970*1270 | |

| Outlet angle | <20mm | |

| 2 guns | ||

| Weight | 25kg |

5.Samples:

|

|

5. Main technical parameter:

| Model | ZH-BH850-4/6 Corner | ZH-BH1100-4/6 Corner |

| Suitable material | Card board 210-800gsm,E/F/N flute corrugated board | Card board 210-800gsm,E/F/N flute corrugated board |

| Max method | Automatic continuous feeding | Automatic continuous feeding |

| Max mechanical speed | 400m/min | 400m/min |

| Overall dimension | 15500*1400*1800mm | 16800*1700*1900mm |

| Weight | 8T | 8.8T |

| Power consumption | 23KW,380V,50HZ | 27KW,380V,50HZ |

| Weight | 7T | 8.8T |

| Compressed air | 6 bar,10 m³/h,60 L | 6 bar,10 m³/h,60 L |

| Inching speed | 10 m/min | 10 m/min |

| Glue type | Cold glue | Cold glue |

8.Machine configuration

9.Standard & Optional configuration list

| Configuration | Units | Standard | Optional | |

| 1 | Feeder section | √ | ||

| 2 | Paper Alignment Section | √ | ||

| 3 | Pre-fold Section | √ | ||

| 4 | Crash lock bottom section | √ | ||

| 5 | Upper paste barrel equipment | |||

| 6 | Down pasting equipment (double side) | √ | ||

| 7 | KQ gluing system 3 guns | √ | ||

| 8 | Grinder device | √ | ||

| 9 | Plasma treatment system | √ | ||

| 10 | Folding and closing section | √ | ||

| 11 | Trombone section | √ | ||

| 12 | 4-6 corner | √ | ||

| 13 | Table | √ | ||

| 14 | Press section | √ | ||

| 15 | Squaring section | √ |