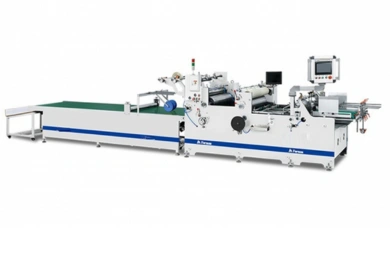

Full autohighspeedwindow

patchingmachine

Product Description

Intemittent Length Sitting:

Suitablepatchingfortheuniversalwindow,andalsopatchingforthenapkinboxincision.Fordoubleasymmetricwindowsinonesheet,thatcanbecustomizedaccordin

Double Line Model: Suitablefortheuniversalpalching,andalsodoublelinepaperpatchingtoimprovetheworkingefficiency.

Double Line Model: Smal Paper High Speed Model:Suitableforthehighspeedpaperpatchingforthesmallpaper,thespeedimprovetwotimesthanthecommonmodel.(16000pcs)

Small Paper for for Double Line High Sped Model:Suitableforthedoublepatchingforthesmallpaper,doublepatching,thespeedimprovefourtimesthanthecommonmodel.