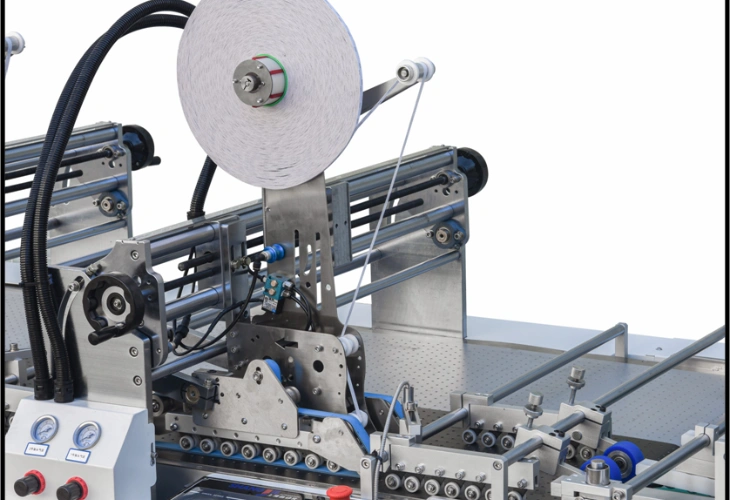

Tape Applicator

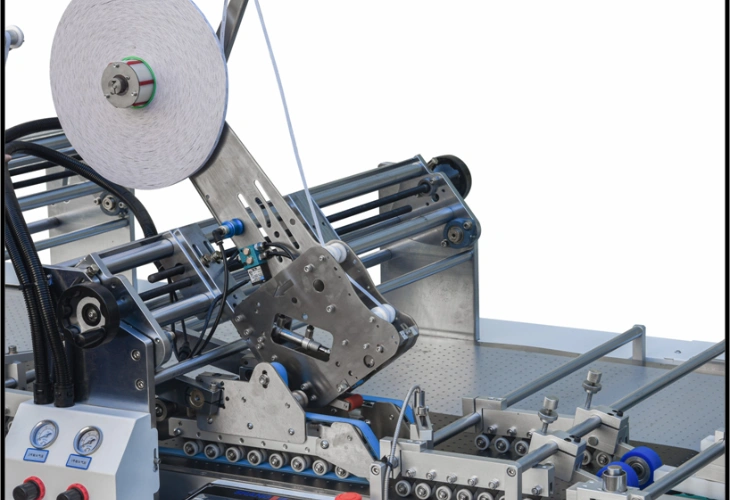

This device is a fully automatic double-sided tape machine used for applying double-sided tape and easy-tear tape to flat paper products such as cardboards, cartons, paper boxes, envelope, and document bags.

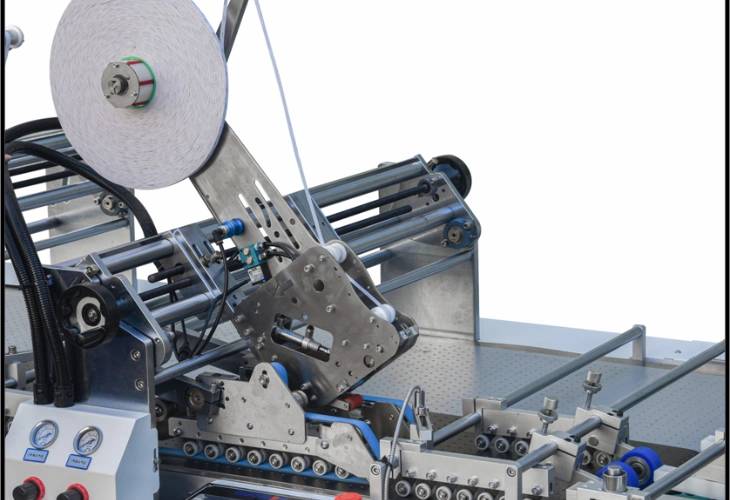

Automatic feeding, the paper feeding part adopts friction feeding method.which can output paper efficiently and can ensure smooth feeding

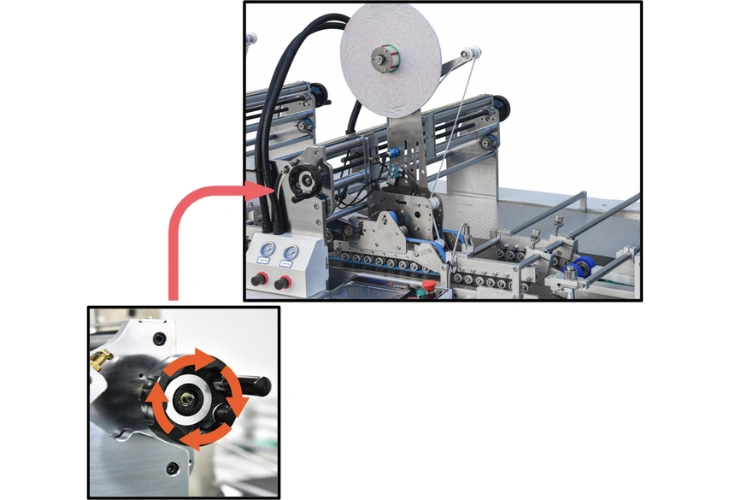

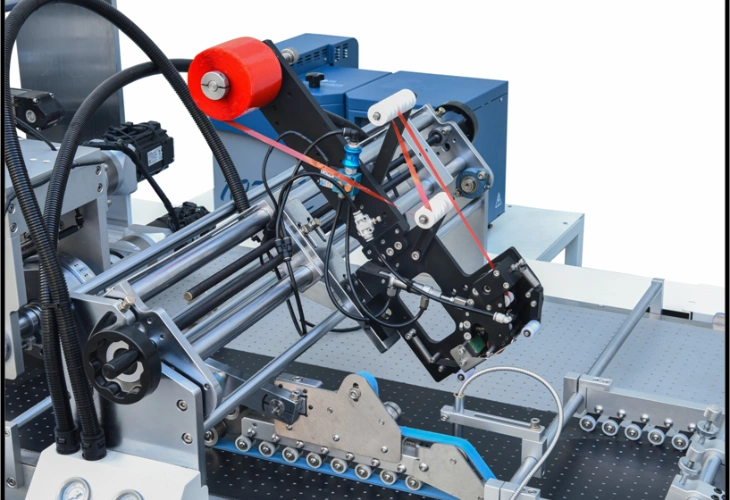

The main body of pasting is divided into front and rear stations to install pasting parts for applying double-sided tape. It can apply 2 parallel strips of double-sided tape at close range at the same time. Up to 4 pasting heads can be installed at the two stations.

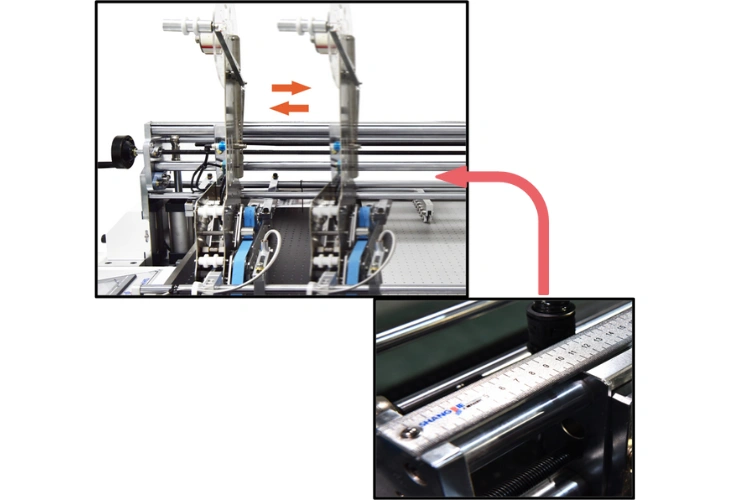

The paper delivery part adopts a separate assembly line continuous boxa ccumulation method