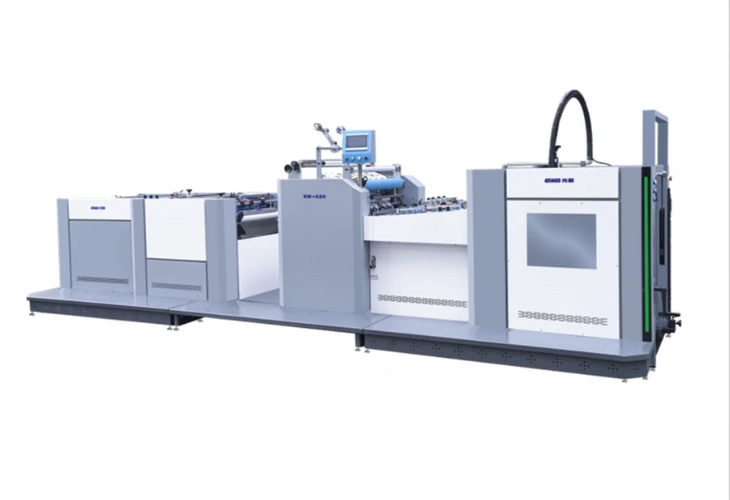

SW-820B / 1050B / 1200B Fully Automatic Double Sided Thermal Film Laminator Manufacturers In Chennai

Filigree, best SW-820B / 1050B / 1200B Fully Automatic Double Sided Thermal Film Laminator Manufacturers In Chennai offers a wide range of automatic laminating machines that are designed for printing products, including posters, photos, cards, packaging boxes, book covers, etc. The latest technique greatly improves lamination effect of dark colour products with no blushing, blisters and mottles. The machine featuring a user-friendly design, refined appearance, is a quick make ready, extremely versatile thermal laminator, with excellent laminating productivity. It has a modular design to add options such as a non-stop pre-stacker, powder removal assembly, chain knife sheeting system, or non-stop stacker.